Description

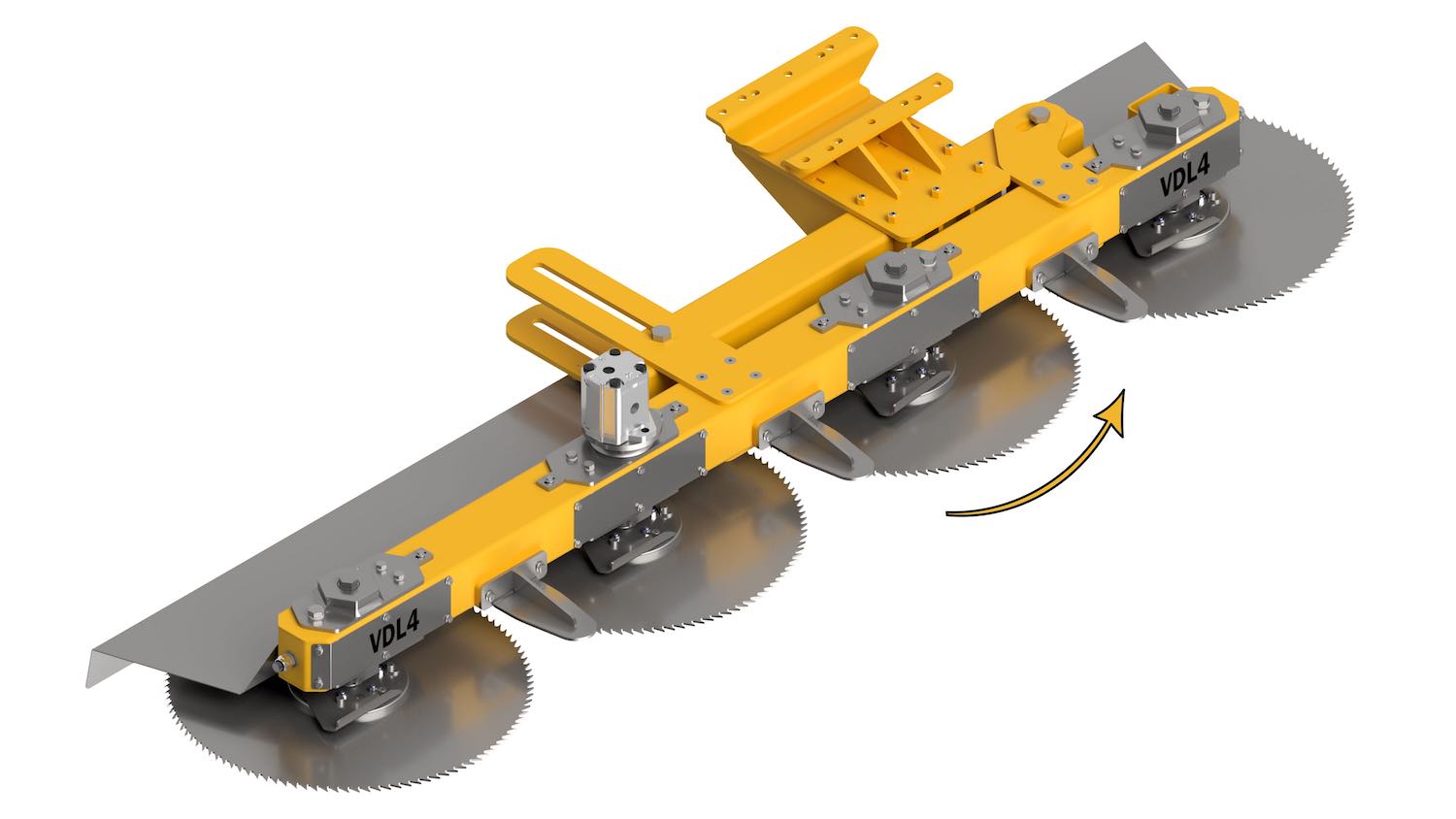

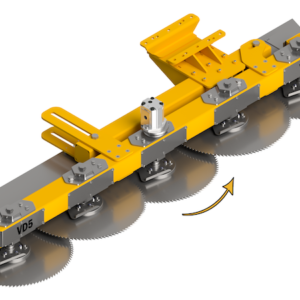

| Model | Weight (kg / lb) | Disc Diameter (mm / ft) | Disc number | Motor number | Bar width (mm / ft) | Cutting Capacity (mm / ft) | Maximum pressure (bars) | Maximum oil flow (L / gal / min) | Transmission |

| VD 2 L | 133 kg

293.21 lb |

600mm

1.96 ft |

2 | 1 | 1225 mm

4.01 ft |

150 mm

0.49 ft

|

150 | 60 lt

15.85 gal |

Driving Belt |

| VD 3 L | 165.5 kg

364.86 lb |

600mm

1.96 ft |

3 | 1 | 1850 mm

6.06 ft |

150mm

0.49 ft |

150 | 60 lt

15.85 gal |

Driving Belt |

| VD 4 L | 200 kg

440.92 lb |

600mm

1.96 ft |

4 | 1 | 2500 mm

8.20 ft |

150 mm

0.49 ft |

150 | 60 lt

15.85 gal |

Driving Belt |

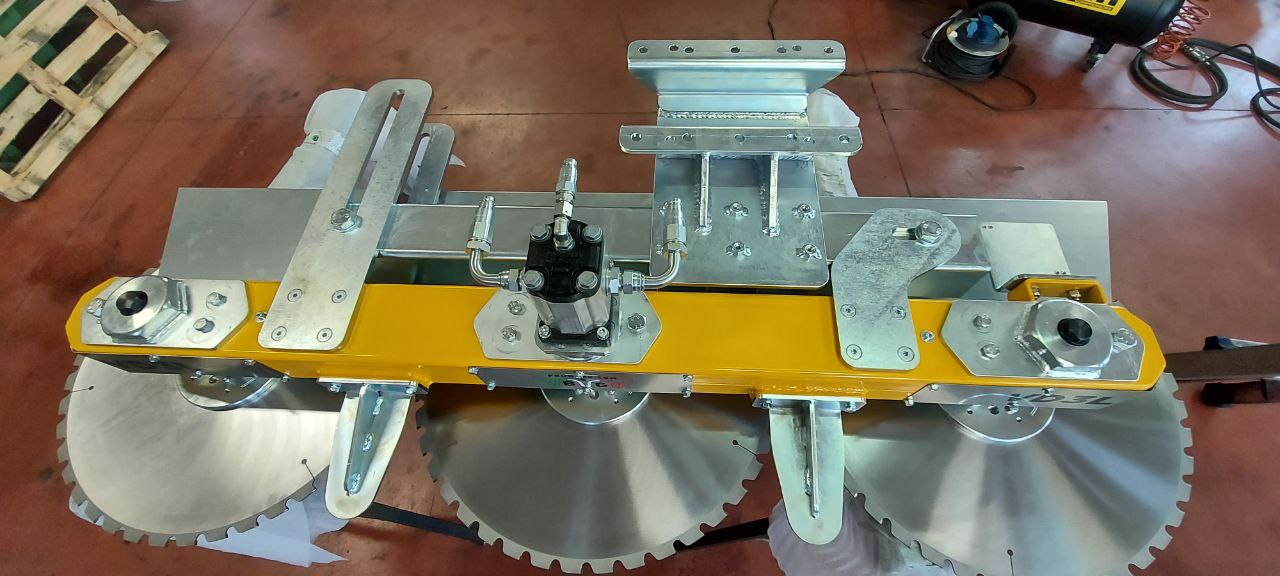

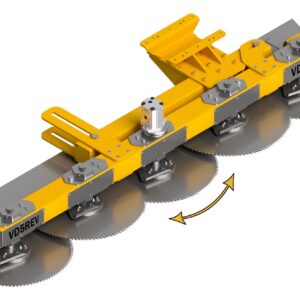

Technical features and standard equipment:

- Hydraulic motor;

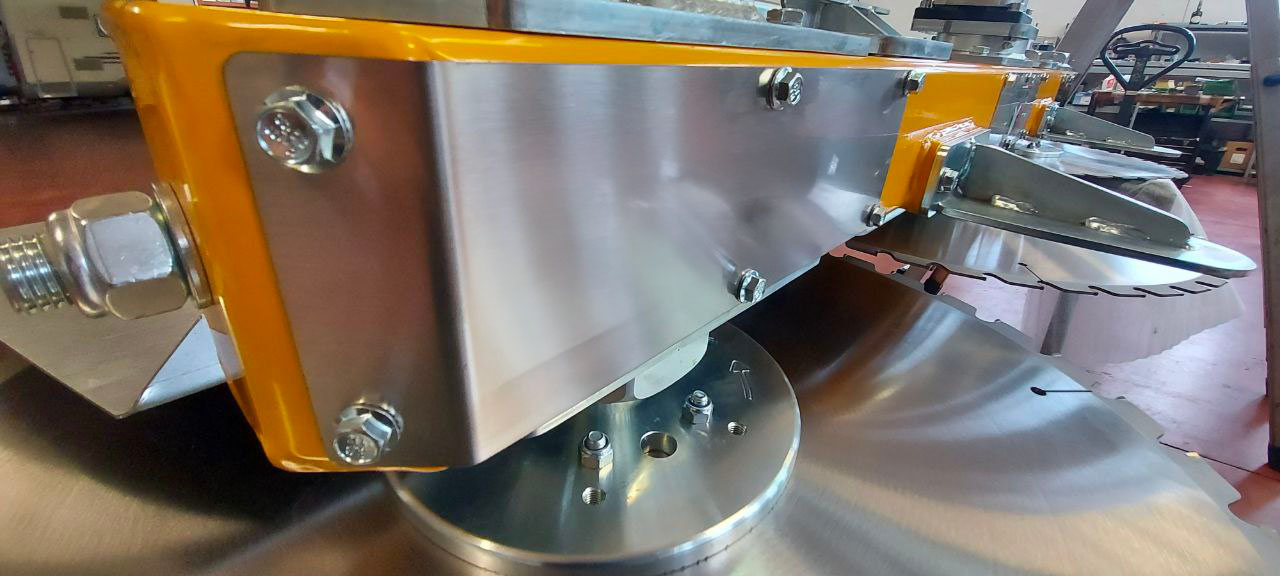

- 600 mm (1.96 ft) Widia disc, 42 teeth;

- Steel plate for excavator or hedge mower mounting hitch;

- Protection blades for transport.

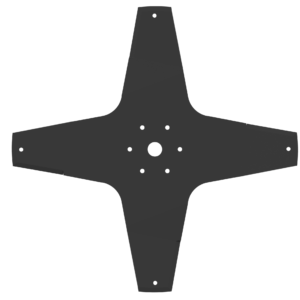

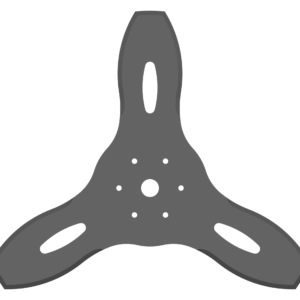

Accessories:

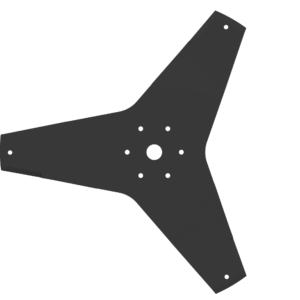

- Disc for green pruning, maximum cutting capacity 15 mm (0.04 ft).

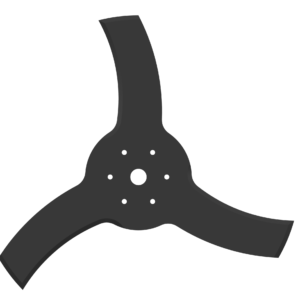

- 600 mm (1.96 ft) Widia disc, 42 teeth;

- 600 mm (1.96 ft) Widia disc, 80 teeth;

- Mounting hitch and pins;

- Valve for adjusting oil flow, anti-shock valve (pressure relief valve), anti-cavitation;

- 2000 mm (6.56 ft) hoses kit, quick couplings excluded.

Instructions for a correct working of disc bars installed on articulated arms

Disc bars with one hydraulic motor

For a correct working of disc bars installed on articulated arms it is mandatory to respect the following rules:

- The articulated arm must carry the disc bar weight indicated in the brochure;

- The auxiliary plant oil capacity must respect what indicated in the brochure, for example “from 45 to 65 litres (11.88 – 17.17 gal) per minute”;

- VERY IMPORTANT: you must have a single-acting auxiliary plant;

- Most articulated arms have a tap allowing you to select the single-acting option (indicated with a hammer).

- To connect the disc bar motor you need to have three pipe lines: a first pipe for oil entrance, a second one for oil escape and finally a third pipe necessary for motor drainage (this pipe must be free at discharge point. To do that it must be connected directly to the oil tank or you can use a T-joint filleted with oil escape pipe near quick coupling connection).

- Do not use agricultural quick couplings, only use industrial flat face quick couplings;

- It is recommended to have an oil cooler;

- Important: all our bar models have a third pipe for external drainage – this solution reduces the motor oil seal breaking risk, assuring a longer life.

- We do not recommend the use of a motor with internal drainage;

- The maximum working pressure is 150 bars.

If you have an hydraulic installation with two pipes only you will have to buy, as an optional, the “regulation, pressure, anti-cavitation valve” available in two models (for 1/2 inch or 3/4 inches pipes).

Provided standard motor is group 2, 25 cc capacity (for installations with 70 litres (18.49 gal) capacity). If your installation capacity is different please write it in the notes when you confirm the order, so we will select the best motor for you, based on the oil capacity. See below:

-

- Engine capacity 8 cc 20 litres (5.28 gal);

- Engine capacity 11 cc 30 litres (7.92 gal);

- Engine capacity 16 cc 40 litres (20.56 gal);

- Engine capacity 22 cc 60 litres (15.85 gal);

- Engine capacity 25 cc 70 litres (18.49 gal).